Silicon Rubber Molding

Prototyping, Small Batch, and Low-Volume Production

Liquid silicone rubber (LSR) is used for countless applications worldwide. Silicone rubber can be used safely in electrical, chemical, and extreme conditions. Gaskets, valves, and parts can all be manufactured using liquid silicone rubber.

Silicone rubber has nearly limitless uses across nearly every industry. Silicone rubber can be made in both small and large quantities, and are available in many different colors.

Silicone rubber resists corrosion, temperature fluctuation, and electrical current placing the potential uses for LSR into the millions!

Industries Include:

- Medical

- Energy

- Automotive

- Electronics

- Aerospace

- Defense

Producing Parts Using Silicone Molds

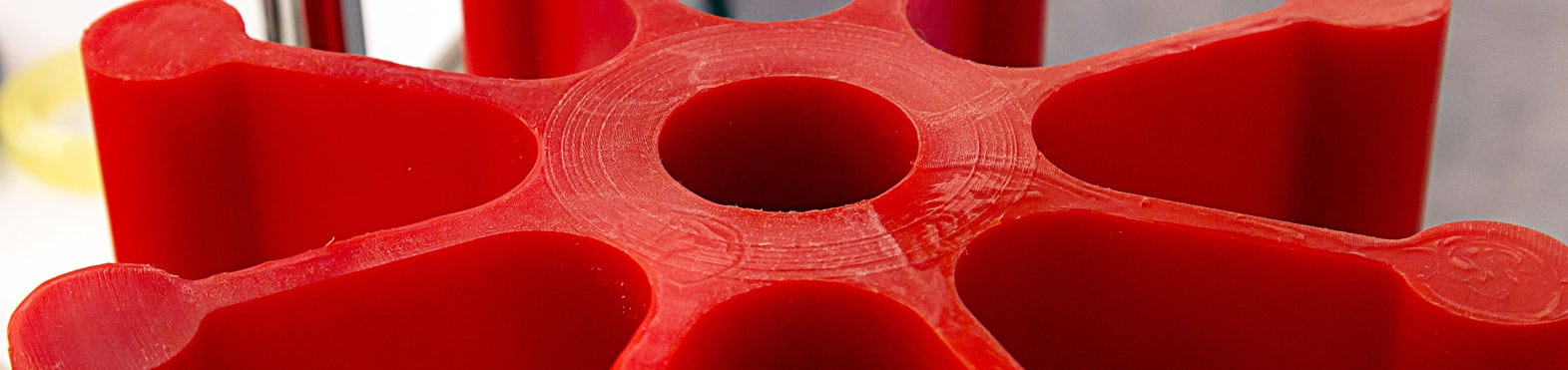

A 3D Printed or CNC Master pattern is created, then silicone rubber is poured around the master to create a rubber mold. The rubber mold is then used to make copies of the master pattern in a plastic resin the emulates Injection Molded plastics. Each mold is good for 15 to 25 parts. Each part can be cast in color with texture.

Silicone Casting

In virtually any color, silicone castings can be made to produce identical units in the dozens up to the hundreds, saving money over metal options.

Silicone Molding

For parts in high quantity, LSR is the production solution. A single metal mold can produce thousands of identical rubber parts in nearly any color imaginable. Low-volume silicone rubber manufacturing is fast, efficient, and extremely competitive in pricing.

The Liquid Silicone Molding (LSR) Process

Liquid silicone molding is a fast and reliable processor for small-batch and low-volume manufacturing of identical silicone casts. Parts made with silicone rubber are identical, resilient, lightweight, and reliable.

Design

Every product starts with a design. Send your CAD file directly to us, or provide your master part model from which the mold will be created. Once your specifications are complete, the design is sent for production.

Mold Creation

Molds are created in-house, saving costs and time. Using our CNC machine shop, master models are created and prepared before being used for the molding process.

Silicone Part Casting

Chilled rubber is injected into a heated mold, then cured. The result is a rubberized realization of your design which will not melt or warp when subjected to heat. Whether your order is for a single prototype or in the thousands, all units are thoroughly inspected for quality and capability before leaving our factory.

Welcome to Mechplus: where innovation and precision in the world of Moulding tool manufacturers come together. As leading manufacturers of Moulding tools, we are driven by a commitment to give you solutions that meet the highest standards in the industry. We specialize in developing molds that are innovative enough to beat all engineering odds ensuring every product you make stands on quality and rigidity.

Mechplus has gained insight into the importance of using exceptional tools in manufacturing ; hence, we have become one of the most reliable suppliers of Moulding tools. Our technologically up-to-date plants enable us to produce products that meet your expectations and go beyond them . From drafting designs at the first stage until final manufacture, our technical team is devoted towards offering tailor-made solutions based on your needs.

Innovation is embedded within our DNA. Being trendsetters among mold-making suppliers stimulates us to pump resources into R&D ahead of any others. This passion for constant innovation guarantees not only reliability but also state-of-the-artness of our products thus giving you an edge over your rivals.

Partnership with Mechplus is something more than just tool purchase – it means having a trusted companion in production. Our reputation is grounded on quality assurance, accuracy and customer satisfaction ratings that are very high. When you go for Mechplus, you opt for someone who cares as much about success as you do.

Go through our diverse range of Moulding tools see how Mechplus can help lift your manufacturing capabilities higher! Let's shape tomorrow's production today!

Request a Free Quote Today

Liquid silicone rubber (LSR) parts have uses in nearly every aspect of daily life. We encounter them all day without noticing. Parts made with liquid silicone rubber have:

- Mechanical uses

- Electrical applications

- Automotive applications

- Extreme temperature resistance

- Sterilization capability

- Many more applications!

If you're ready to talk about your liquid silicone rubber manufacturing project, contact us today for your free quote. Not sure? Let us answer your questions. Give us a call and our staff will be happy to help you however possible.